Wabash - What Is It?

-

Wabash looks like quite a formal fabric, but in fact it was commonly used for work wear from the early 1800s through to the early 1900s, very often as uniforms for the massive US railroads work force. Finding out a lot about Wabash is very difficult, but we believe there were 2 ways in which the dots were originally “applied” to the base fabric: 1) the pattern would be applied as a block print to the undyed fabric with a starch based “resist” and then dyed, the dye not adhering to the resistant pattern; and 2) the fabric was dyed and then the pattern bleached into the fabric - this was done by applying a mildly acidic solution to the cloth via copper rollers with the pattern raised from the surface of the roller, a process known as discharge printing.

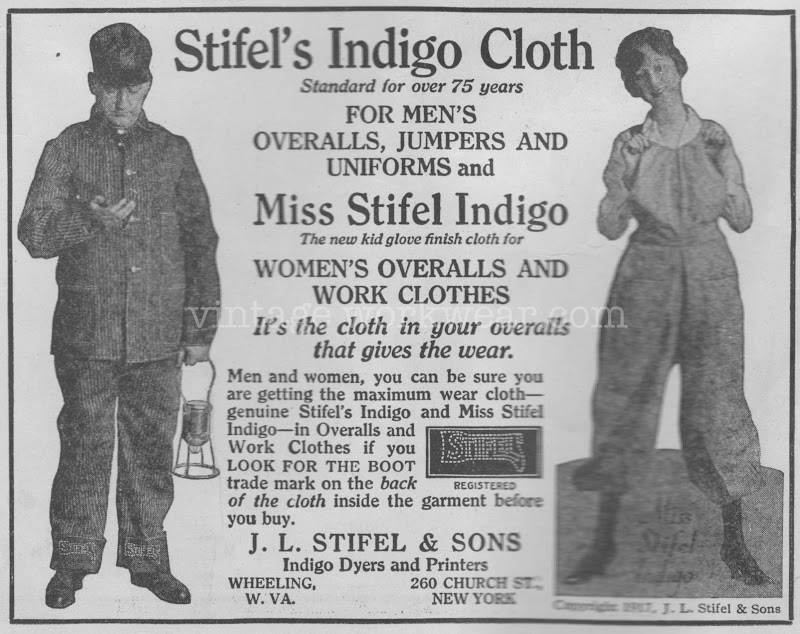

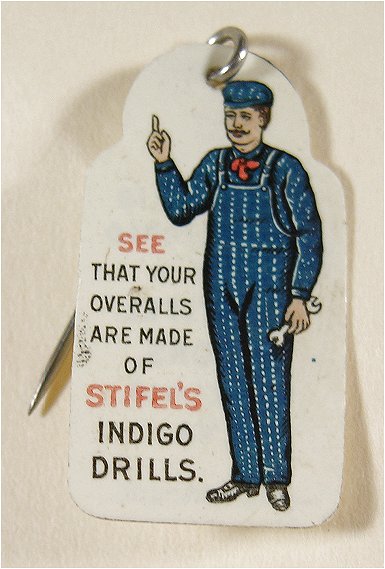

Perhaps the most famous of the American Wabash dying and printing companies was J.L. Stifel & sons set up in West Virginia in 1835. They called their product "Indigo Wabash Stripe" and it was often characterized by an impressive assortment of dots, triangles and diamonds. A few examples of these can be found in "King of Vintage vol 3" by Rin Tanaka.

Our latest Wabash fabric, designed from first principles by Haraki, is created utilizing the discharge printing technique. Both the weft and the warp are separately indigo rope dyed and then woven to create a 12oz denim fabric. This fabric is then discharge printed to create the dots. Because we use a rope dying technique for the base fabric, the garments created from it will age with great character.

-

Interesting stuff G!.. Brilliant fabric

-

I really enjoyed reading this info in the latest newsletter. Dropping some heavy knowledge and Kiya's contribution is the icing on the cake. Cheers.

-

How is the fabric on the old IH wabash dyed? I'm wearing my 55 today and would love to know.

-

Pretty sure it's a discharge print, just like the new version.

-

But there will still be fading in areas of wear, correct?

(just not as much as the new wabash is my understanding)

-

Old wabash is perfect for those who seek a quick evo fix …

-

-

Great images Urb.

-

Check out e-workers.net. He's the dude that went to Virginia and found the old wabash directions in the basement of a mill. He then had a Japanese mill reproduce the exact fabric. I'd love to see the directions and if they call the twill weave a 2x1 denim or something different.

-

Check out e-workers.net. He's the dude that went to Virginia and found the old wabash directions in the basement of a mill. He then had a Japanese mill reproduce the exact fabric. I'd love to see the directions and if they call the twill weave a 2x1 denim or something different.

thats a trip. finding a "recipe' like that and having it reproduced is f'ing cool

-

Yeah, I don't think there are any repro brands that are better than Workers right now. I bet their wabash is something special. I'd assume lighter weight than IH wabash though. Or who knows, might be made in the same place.